Chute Wear Rubber Ceramic Wear Plate Mat Lining Abrasion Wear Resistant Ceramic Liner

Overview Package size per unit product 20.00cm * 30.00cm * 5.00cm Gross weight per unit product 10.000kg Product Descrip

Send your inquiryDESCRIPTION

Basic Info

| Model NO. | Ceramic Lining |

| Model Number | Xt-Tcm |

| Brand Name | Xintong |

| Processing Service | Hot Vulcanizing |

| Product Name | Ceramic Mat Manufacturers Rubber Ceramic Chute Lin |

| Al2O3 Ceramics | 92% & 95% Al2O3 |

| Advantage | Ceramics Will Stay in Place Until Completely Worn |

| Production Process | Our Special Mold, Hot Vulcanization |

| Size | Available with All Sizes and Shapes |

| Factory Since 1996 | Rich Experience,Mature Production,Strict QC |

| Industry | Mining, Aggregate, Cement, etc. |

| Certificate | ISO, SGS |

| Keywords | Ceramic Rubber Lining Pad Ceramic Tiles on Rubber |

| Sample | Free |

| OEM | Logo |

| MOQ | 100 Sets |

| Transport Package | Wooden Box |

| Specification | available with all sizes and shapes |

| Trademark | XIntong |

| Origin | China |

| HS Code | 6903200000 |

| Production Capacity | 5000PCS/Month |

Packaging & Delivery

Package size per unit product 20.00cm * 30.00cm * 5.00cm Gross weight per unit product 10.000kgProduct Description

Conveyor Wear Solutions: Ceramic Rubber Liners

Our Ceramic Rubber Liners are made of extremely hard ceramics that provide unsurpassed resistance to abrasive wear while the rubber effectively dampens the impact forces that can crack the ceramic rods. The resilient rubber matrix that surrounds the ceramic rods is hot vulcanized for superior adhesion.Structures of Ceramic Rubber Liner

Alumina Ceramic: 92% & 95% Ceramic, available with extensive sizes and shapesRubber/PU Layer: Superior compound rubber/ polyurethane, impact-absorbing

Connection: Steel plate & studs, CN bonding layer,et.

Excellent bonding: Ceramics,rubber and steel plate are permanently bonded through our special molding and hot vulcanization process. Ceramics will stay in place until completely wornSpecifications

When selecting wear liner, the following information should be taken in account:

-- Material and lump size,--Drop height,

--Impact angle

Selection Guide is available, you could choose what you require, or let us recommend suitable types according to your wear, impact protect requirement. The thickness of complete liner, ceramic and rubber are determined on the basis of application, such as handled material lump size, height of fall, impact angle, etc.

Standard Size:XT-TCM-IUsed for light abrasion applications and light impact or no impact. Spherical ceramic tiles are suitable for light impact.Size of Ceramic tiles: 17.9mm x 17.9mm x5mmSize of Liner: 250mm x 250mm x 16mmXT-TCM-IIUsed for moderate to heavy abrasion and impact applications.Cylindrical ceramic size:Φ20*20mmSteel plate thickness:6mmLiner size: 250*250*36mm, 300*300*36mm, etc.Irregular size on special request.

DB-TCM-IIIUsed for heavy abrasion and impact applications.Cylindrical ceramic size:Φ31*31mmSteel backing plate thickness:6mmLiner size:250*250*51mm, 300*300*51mm, 500*500*51mmOther sizes can be made as request.

DB-TCM-IV

Used for moderate impact and heavy wear applications.Ceramic bricks: 50*50*25mm or 50*50*50mmSteel backing plate thickness: 6mmLiner size: 300*300*35mm/ 300*300*63mm, 500*500*35mm/ 500*500*63mm, etc.DB-TCM-V

Ceramic On Rubber Mat with CN layer:Ceramic size:20*20*4mmLiner size: 500*500*8mm, etc.Vary thickness to suit different applications. Rubber mat supplied with CN bonding layer.CN layer peel strength: ≥12kN/mDB-TCM-VI

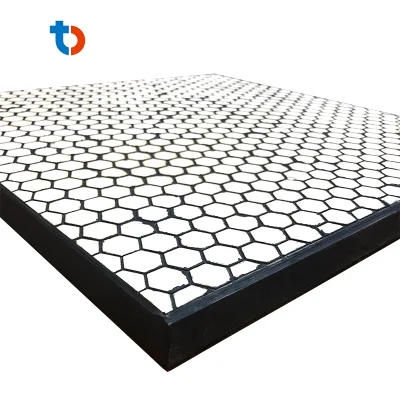

Rubber Liner with Hexagonal Ceramics.Liner size: 500*500mmHexagonal ceramic thickness: 6mm, 10mm, 13mm, 20mm, 25mm, etc.Connection: cn layer, steel plate with studs. Both availableIrregular ceramic wear liners size on special request.Ceramic rubber liner with wear strips, bolt holes and plugs availableCeramics will stay in place until completely worn.Technical Data

Technical Data

| Item | Description | Unit | Result |

| Alumina Ceramics | |||

| 1 | Alumina (Al2O3) | % | 92 / 95 |

| 2 | Density | g/cm3 | 3.64 |

| 3 | Water Absorption | % | ≤0.01 |

| 4 | Hardness | Mohs | 9 |

| Rubber | |||

| 1 | Material | NR, BR | |

| 2 | Gravity | g/cm3 | 1.15 |

| 3 | Tensile Strength | MPa | 16 min |

| 4 | Elongation | % | 400 min |

| 5 | Abrasion Loss | mm3 | ≤80 |

| 6 | Aging coefficient (70ºCx48h) | ||

| Peeling Strength | |||

| 1 | Peeling strength between rubber & ceramic | KN/m | ≥12 |

| 2 | Peeling strength between rubber & steel | KN/m | ≥12 |

1) 22-Year Manufacturer, rich experience ensure quality and consistency.2) Standard size and non-standard sizes are all available3) excellent adhesion between ceramic and rubber4) strict control in QC, advnaced facilities, mature production line5) available with stud bolt and weldable installation methods or CN bonding layer6) 9-Year exporter,ceramic rubber liner got very good feedback.Repeated orders from worldwide customers.

Factory since 1996

1) Over 22 Years experience of producing and developing, Debon Technology have become top 10 belt conveyor accessories factory in China

2) Export since 2009, export to over 45 countries, repeated orders from worldwide customers 3) We've been Alibaba 10 million e-businessman since 2013 4) Rich experience, mature production, strict QC ensure quality and consistency

Main Products:

Related Products

-

![80% Alumina Grinding Ceramic Media for Ball Mil (Titanium dioxide grinding)]()

80% Alumina Grinding Ceramic Media for Ball Mil (Titanium dioxide grinding)

-

![High Density Practical Wear Resistant Economic Ceramic Cylinder Grinding Media]()

High Density Practical Wear Resistant Economic Ceramic Cylinder Grinding Media

-

![20*20*5mm High Density Abrasion Resistant Square Alumina Ceramic Liners for Industrial Applications]()

20*20*5mm High Density Abrasion Resistant Square Alumina Ceramic Liners for Industrial Applications

-

![Ceramic Ball 99 Tabular Alumina Ball as Inert Catalyst Bed Support]()

Ceramic Ball 99 Tabular Alumina Ball as Inert Catalyst Bed Support