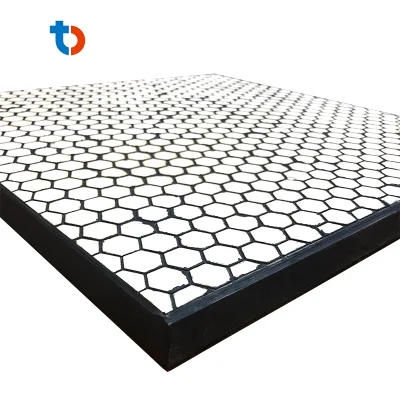

17-23% Industry Media Inert Ceramic Alumina Ball Ceramic Ball

Overview Product DescriptionIntroduction:Inert ceramic (porcelain) balls are used to fill and support the catalyst layer

Send your inquiryDESCRIPTION

Basic Info

| Model NO. | NX-ICB |

| CAS No. | / |

| Formula | / |

| EINECS | / |

| Material | Alumina |

| Structure Feature | Sphere |

| Type | Ceramic Ball |

| Usage | Chemical Industry Product |

| Effect | Catalyst Bed Support Media |

| Source | Ceramic Ball |

| Product Name | 17-23% Ceramic Inert Ball Catalyst Bed Support Med |

| Density | 1.3-2.2kg/Cm3 |

| Alumina Content | 17-23 |

| Key Words | Alumina Inert Ball |

| Moh′s Hardness | >6.5 Scale |

| Size | 3mm,6mm,13mm,19mm,25mm |

| Transport Package | Weave Bag, Jumbo Bag, Pallet |

| Specification | 3-70mm |

| Trademark | NANXIANG |

| Origin | Pingxiang Jiangxi |

| HS Code | 6914900000 |

| Production Capacity | 100ton/Month |

Product Description

Introduction:Inert ceramic (porcelain) balls are used to fill and support the catalyst layer in catalytic columns and reactors, and as grinding bodies in ball mills.The balls are made of high quality solid pressed silicate porcelain with an aluminum oxide content of Al2O3 -17% (in the range of 17-26%). They have high mechanical strength, resistance to acid, alkali, and some organic solvent, and resistance to thermal shock, which makes them all ideal choice for support of all types of catalysts.Ceramic Balls are available to the order of sizes from 3 mm to 50 mm in diameter. Other types of ceramic products can be made upon your request indicating the necessary technical data Ceramic Balls (also known as support ball, inert ball and catalyst support media) were very important component in the catalytic process in the refinery, gas processing and petrochemical industry. Its main function is to act as packing material and at the same time to support the catalyst bed in order to prevent breakthrough or loss of catalyst or adsorbent materials downstream of the reactor vessels due to the high pressure and temperature inside the reactor vessels during the operation. Ceramic ball come up with a few different sizes, which are 1/8", 1/4", 3/8", 1/2", 3/4", 1", 1¼", 1½", 2". The size was arranged layer by layer at the top and bottom of the vessel, with different sizes of ceramic ball. Chemical reaction in a reactor (designations on the diagram):The raw materials flow down from the upper part. The raw materials go through the inert balls, to the catalyst area. The raw materials chemically react at the catalyst area and get chemically engineering. It becomes the secondary raw materials (products).The chemical engineered materials (products) pass through the inert balls and flows to next process. Application:Production and Application of Inert Ceramic (Porcelain) Balls as supporting carriers for catalysts, absorbents, as molecular sieves; to fill the reaction apparatus, they act as a distributor of reagents and coolant in the petrochemical and chemical industries; as grinding bodies for milling materials in ball mills when grinding and mixing chemicals, pharmaceuticals, dyes,grinding metal surfaces, grinding food raw materials in the food industry. The balls have extremely low water absorption (real <0.1%), high acid resistance (>99.6%), and a long service life subject to operating conditions. Porcelain balls are made of silicate (alumina) porcelain by powder compaction of the mass, molding, pulling through the mouthpiece, with diameters ranging from 3 mm to 50 mm. Other types of ceramic products can be made upon your request indicating the necessary technical data. Product ParametersChemical Composition| Al2O3+SiO2 | Al2O3 | Fe2O3 | MgO | K2O+Na2O +CaO | Other |

| > 92% | 23-26% | <1% | <2.5% | <4% | <1% |

| Item | Value |

| Water Absorption (%) | <0.5 |

| Bulk Density (g/cm3) | 1.35-1.4 |

| Specific Gravity (g/cm3) | 2.3-2.4 |

| Free Volume (%) | 40 |

| Operation Temp. (max) (ºC) | 1100 |

| Moh's Hardness | >6.5 |

| Acid Resistance (%) | >99.6 |

| Alkali Resistance (%) | >85 |

| Size | Crush Strength | |

| KG/Particle | KN/Particle | |

| 1/8" (3mm) | >35 | >0.35 |

| 1/4" (6mm) | >60 | >0.60 |

| 3/8" (10mm) | >85 | >0.85 |

| 1/2" (13mm) | >185 | >1.85 |

| 3/4" (19mm) | >487 | >4.87 |

| 1" (25mm) | >850 | >8.5 |

| 1-1/2" (38mm) | >1200 | >12 |

| 2" (50mm) | >5600 | >56 |

| Package Type | Container Load Capacity | Delivery Time | Quality Insurance | Payment Terms | |

| 20 GP | 40 GP | ||||

| Steel Drum | 20-24 tons | * | Within 7 days | China National Standard; Offer quality assurance as request | T/T, L/C, Paypal, West Union |

| Ton Bag | 20-25 tons | * | |||

| Woven Bag | 20-25 tons | * | |||

Pingxiang Nanxiang Chemical Packing was established in 2003, It is a professional manufacturer and exporter that has more than 20 years experience in Chemical Packing. We are located in West Section Hi-Tech Industry Park Pingxiang City, Jiangxi Province, with convenient transportation access. All of our products comply with international quality standards and are greatly appreciated in a variety of different markets throughout the world.

Our main products are molecular sieve, activated alumina, ceramic ball, honeycomb ceramics, random and structured chemical packing in ceramic, plastic and metal material, can be used in all types of petrochemical chemical processes and environmental application.

Our well-equipped facilities and excellent quality control throughout all stages of production enables us to guarantee total

customer satisfaction. Besides, we have received ISO9001:2008 certificate, SGS report, and credible merchant of Alibaba. As a result of our high quality products and outstanding customer service, we have gained a global sales network reaching seven Continents.

Since its foundation, our company keeps living up to the belief of "honest selling ,best quality ,people-orientation and benefits to customers" We are doing everything to offer our customers with best services and best products .We promise that we will be responsible all the way to the end once our services begin.

If you are interested in any of our products or would like to discuss a custom order, please feel free to contact us. We are

looking forward to forming successful business relationships with you, also warmly welcome to visit our factory.

1.Who are we?

We located in Pingxiang City, known as "Hometown of Chemical Packing", established in 2003, have over 10 years export experience, there are 50-80 workers in our company. Products sell to Domestic Market (30%). Southeast Asia (15%), Mid East (10%), Europe (20%), South America (5.0%), North America (15%), Africa (5.0%).

2.How can we guarantee quality?

We have QC during production, and after product finished Samples can provide before order Inspection can be done before shipment if needed

3.What can you buy from us?

Plastic,ceramic,metal random and Structured tower packing, Ceramic Ball, Molecular Sieve, Silica Gel, Various kinds of ceramic bio ball for water treatment

4. What payment term can we do?

We accept payment type like T/T, L/C, PayPal, MoneyGram, Western Union etc.

5. What services can we provide?

Accept customized according to your requirements.Accept Delivery Terms: FOB,CFR,CIF,EXW,FCA,DDP,DDU,Express Delivery.Accept Payment Currency:USD,EUR;RMBNo strict require on the MOQ, accept small order

Related Products